-

- Plating Team #1

- Hard Chromium Plating, Porous Chromium Plating

Hard Chromium Plating

Hard Chromium Plating- - It is used to enhance various properties, such as high abrasion resistance, lubricity, thermal resistance, corrosion resistance, deformation resistance, etc.

- - It uses methodology of which makes hexavalent chromium revert to electric properties in Chromium Trioxide(CrO3) with sulfuric acid added.

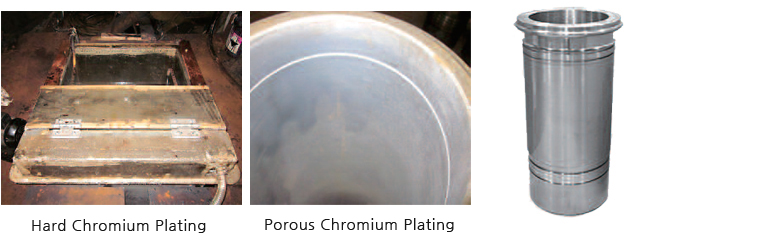

Porous Chromium Plating

Porous Chromium Plating- - It means chromium plating with many cracks, where it enhances abrasion resistance of internal engine cylinder or piston ring, and it further makes up small roundy nip on the chrome plating to extend life expectancy, maintaining good lubricity.

Feature of hard chromium plating

Feature of hard chromium plating- - It is possible to obtain high hardness of Hv 700 ~ 1,000 from internal stress occurred when crystal gain of plating layer gets refined and electrodeposition.

- - It contains excellent abrasion resistance, low friction coefficient and good thermal resistance.

- - It has good isolating property of which refuses foreign substances.

- - Crack exists within the plating layers; it is used to enhance lubricity by permeating lubricants into the crack, by means of applying the characteristics of crack to the piston or cylinder.

- - It shows terrible characteristics on plating bath, such as balanced deposition, covering power, etc., due to low cathode current efficiency, compared to other plating.

- - No corrosion possible, other than hydrochloric acid.

Business Status

Business Status  Business area

Business area

Hard Chromium Plating

Hard Chromium Plating Porous Chromium Plating

Porous Chromium Plating Feature of hard chromium plating

Feature of hard chromium plating