-

- Plating Team #2

- Tin Plating, Tin-Lead Alloy Plating

Tin Plating

Tin Plating- - It is used to enhance soldering performance, corrosion resistance, adhesion prevention, sliding and lubricity.

- - Types of plating bath in use include sulfuric acid bath, fluoborate bath, sulfonic bath, alkalin bath(tartrate, pyrophosphate), etc.

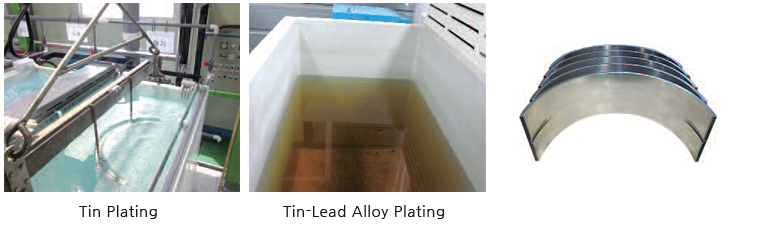

Tin-Lead Alloy Plating

Tin-Lead Alloy Plating- - It is used to enhance soldering performance, acid resistance, sliding and lubricity.

- - It is often called as tin-lead alloy plating, and types of plating bath in use include fluoborate bath, sulfonic bath,etc.,and it allows balanced deposition plating over the bearing surface.

Feature of Tin Plating

Feature of Tin Plating- 1)Tin is soft and highly expandable, where melting point is low with 231.93 Celcius and boiling point is with 2602 Celcius.

- 2)It is silver gray metal with thermal conductivity is one third of silver, and the electricity conductivity is 1/7 to that of silver.

- 3)Tin is less harmful to human organs; for this it is used in making dishes or plating them. Also, it can be used for plating inner surface of cans due to strong organic acid resistance.

- 4)It excels in solding performance, therefore is widely used in electronic/electric goods.

- 5)Tin plating on Fe substrate, unlike zinc plating, progresses corrosion quickly, due to substrate becoming positive node; therefore undercoating is required.

- 6)It enhances lubricity and operability by electro tin plating over engine driving parts, pistons, etc.

Business Status

Business Status  Business area

Business area

Tin Plating

Tin Plating Tin-Lead Alloy Plating

Tin-Lead Alloy Plating Feature of Tin Plating

Feature of Tin Plating